-

GM-300 Auto Lensmeter is our latest model in Topcon style. It has functions of PD, UV, printer and

blue light measurement. It can measure colorful and dark lenses at fast speed and in high accuracy.1. 5.6″ sensitive colorful KEY MODE screen;

2. Fast speed PD, UV and blue light measurement;

3. The machine can measure colorful lens and dark lens;

4. Hartmann sensor with 108 measurement points;

5. Fast and accurate test measurement. -

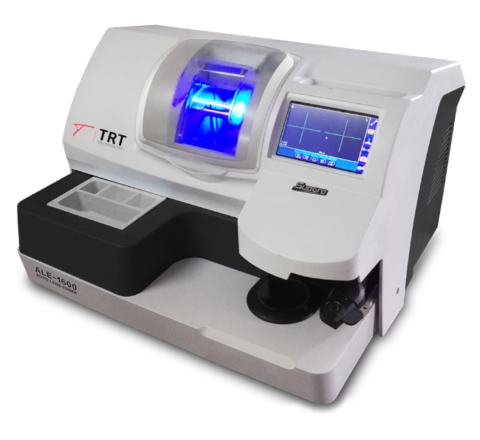

with built-in lens scanner , 3D lens scanner

ALE1600 without lens groover function

ALE-1600G With lens groover , and safe chamfering

1. 7 inch hd LCD touch screen:Resolution 1024×600;

2. Data storage:The scan data can be saved when power down and can store 500 template data;

3. Date form change:The scanned shape could be changed freely (to zoom in or out from left to right, from up to down, from lower edge, or to zoom in and out from axial position);

4. Easy operation interface

5. Quick scan: 3 seconds;

6. Preview interface can input PD, PH conveniently;

7. For different material lens processing requirement ( Cr-39, PC, HC,HI, glass, etc) ;

8. Adjusting bevel position freely:The user can adjust full frame ratio by themselves (Auto, 33%, 55%, Bend forwards , Curve backward , etc. )

9. Precision, no-parallax optical scanner, optical center meter, with fast scanning speed, low failure rate;

10. Combined Scanner with Center meter as one;

11. External storage containers can provide easy storage for customer;

12. Built-in wheel with diameter of small specification90mm, with fast processing speed.

-

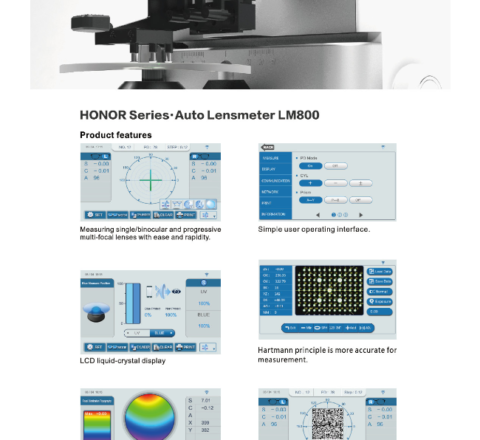

LM-800Lens Meter can measure the single focal, Bi—focal and progressive lenses simply, quickly and accurately.

– More accurately measurement under the Hartmann principle

– QR code printing without paper

– The all-in-one printer provides better solution for printing paper replacement

– High-resolution truecolor screen

– User-friendly menu for progressive measurement

– Self-calibration function of the software -

Features:

1. 7.0”sensitive LCD display touch screen;

2. All operations can be finished by touching screen;

3. Tiltable screen by angle from 20°~120°;

4. Advanced Hartmann sensor technology with 108 measurement points;

5. Adopted green measurement light beam allows to measure different kinds of dark lenses;

6. Point is made by nanomaterials, and there is no damage to the Lenses;

7. Progressive measurement to improve accuracy and speed of near and far vision measurements;

8. Auto recognition of single and progressive lens;

9. High speed UV measurement and built in Thermal Printer. -

– Green measurement light

– Hartmann sensor

– 7.0 inch touch screen -

1. LM-700 Lens Meter can measure the single focal, Bi-focal and progressive lens simply, quickly and accurately.

2. More accurately measurement under the Hartmann principle.

3. QR code printing without paper.

4. The all-in-one printer provides better solution for printing paper replacement.

5. High-resolution true color screen.

6. User-friendly menu for progressive measurement.

7. Self-calibration function of software.

-

Equipped with specific materials , the LE-620 auto lens edger inherits the design style of Supore , LE series auto edger , easy to operate and able to process lens size accurately and stably

– Beveling polishing function

– Pressurizing automatically

– PC auto edger

– The 3rd generation mainboard

– Double Bevel model -

-

Equipped width specific materials, the LE-420 auto edger inherits the design style of Supore LE series auto edger, easy to operate and able to process lens size accurately and stably.

Added the automatic emendation system in this new model .it can do automatic emendation when the machine start up assure the size of lens (left and right )is uniform and improve the precision.

– The 3rd generation mainboard

View Basket “LE-420 Auto Lens Edger” has been added to your cart.